With the increasing awareness of plastic pollution and a push for sustainability, the question arises: Can PET plastic recycling machines recycle daily necessities? Let’s explore how PET recycling technology fits into our everyday efforts to reduce waste.

What is PET?

PET stands for Polyethylene Terephthalate. It’s a type of plastic widely used in packaging and products we see every day. You’ll find PET in water bottles, soda bottles, food containers, packaging films, and even some synthetic fibers. Its popularity comes from being lightweight, durable, transparent, and—most importantly—recyclable.

What are Daily Necessities Made from PET?

Many daily necessities are made from PET plastics, including:

- Beverage bottles (water, juice, soda)

- Food packaging (trays, clamshell containers, jars)

- Personal care products (shampoo bottles, liquid soap containers)

- Household cleaning product bottles

- Certain textiles and fibers (clothing, tote bags—though recycling these requires a different process)

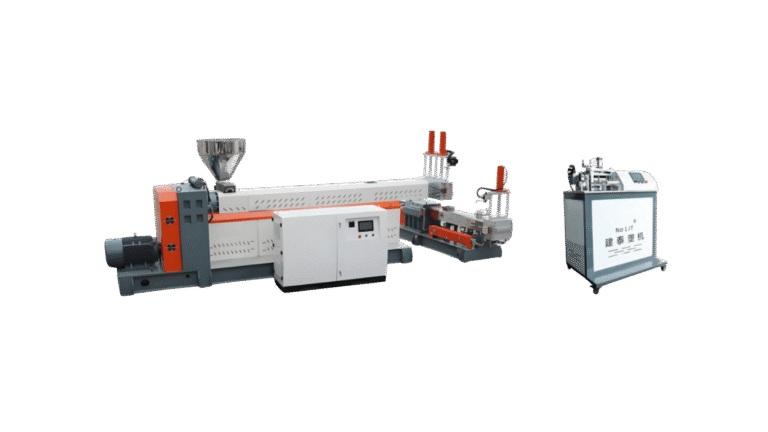

How Do PET Plastic Recycling Machines Work?

PET plastic recycling machines are designed to process and regenerate PET waste. Here’s a simplified workflow:

- Collection & Sorting: Used PET items are collected and separated from other plastics.

- Shredding: Items are shredded into small plastic flakes.

- Washing: Flakes undergo hot and cold washing to remove labels, residues, and contaminants.

- Separation: Any non-PET material is removed, ensuring purity.

- Melting & Pelletizing: Clean flakes are melted and extruded into pellets, which can be used to manufacture new PET products.

Can PET Recycling Machines Handle All Daily Necessities?

YES—for many daily PET products. Most single-use PET bottles and food containers are highly recyclable with current technology. The process is efficient and well-established worldwide.

However, there are some challenges:

- Multi-layer or composite packaging, which combines PET with other materials, is difficult to recycle.

- Coloured or heavily contaminated PET is less desirable but can still be processed with advanced sorting and cleaning.

- Labels, caps, and closures often use different plastics, requiring separation before recycling.

- Personal care or chemical product bottles must be thoroughly cleaned to avoid chemical contamination during recycling.

The Sustainable Impact

By feeding PET bottles, food packaging, and other necessities into a recycling machine, we keep valuable plastic in use and out of landfills. The recycled pellets can be turned back into new bottles, containers, packaging materials, and even textiles, creating a true circular economy.

Conclusion

PET plastic recycling machines effectively recycle many daily necessities, especially single-use bottles and food containers. While not every PET-based item is easily recyclable (mainly due to mixed materials), improvements in recycling technology are broadening the possibilities. By choosing products made from PET and participating in recycling programs, we can all help make a difference.

Ready to learn more about how PET recycling machines can help your community or business go green? Contact us for a consultation or check out our guide on choosing the best PET recycling solutions!