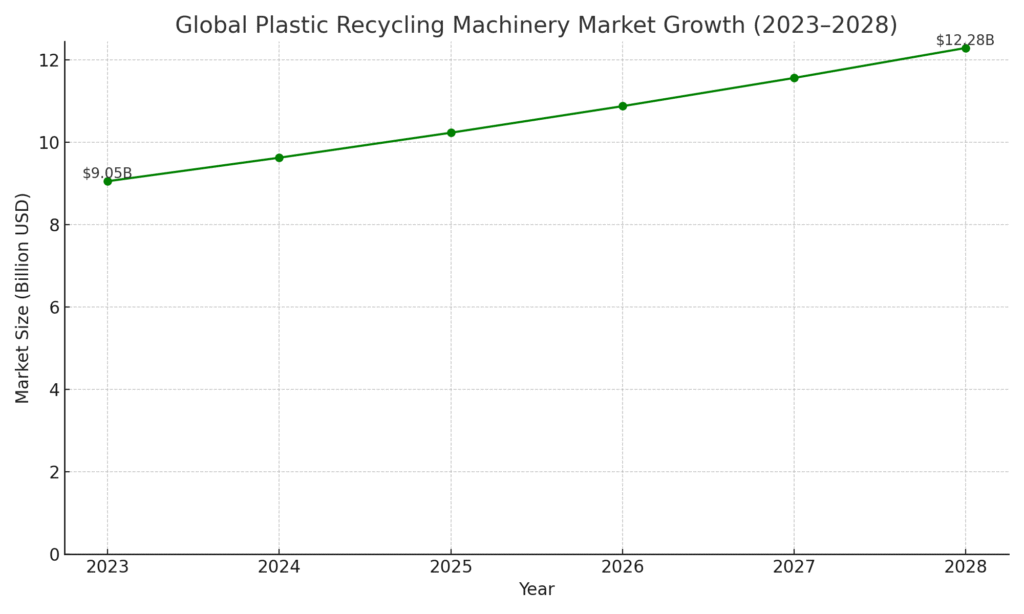

According to multiple industry research reports, the global plastic recycling machinery market is expected to achieve significant growth in the coming years. For example, Mordor Intelligence estimates that the global plastic recycling machinery market is worth approximately $9.05 billion in 2023 and is expected to reach approximately $12.26 billion by 2028, with a CAGR of approximately 6.3% during the forecast period (2023-2028).

What is a plastic recycling machine?

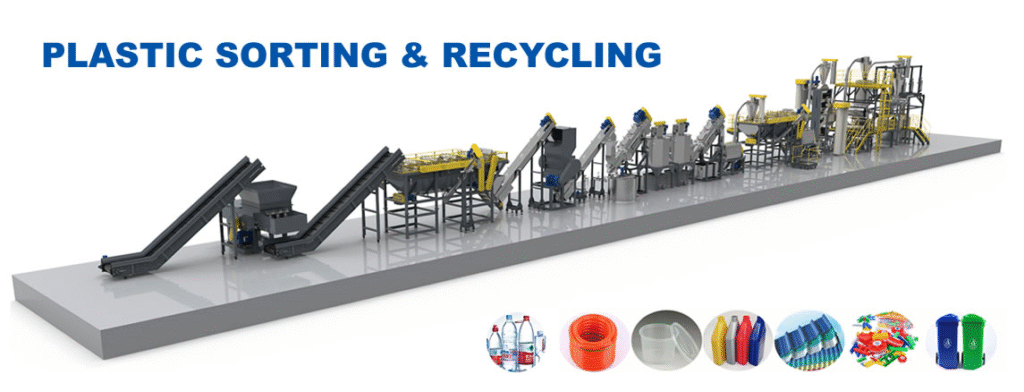

Plastic recycling machines are industrial equipment that processes waste plastic into reusable raw materials. These machines convert discarded plastic products (such as bottles, packaging, bags and other plastic fragments) into plastic pellets, which can then be used to make new plastic products.

Working Principle of a Plastic Recycling Machine

Plastic recycling machines convert waste plastics into reusable raw materials through a series of mechanical and thermal processes. Its main principle is to recover old plastics and convert them into granules or pellets that can be reused in the manufacturing process.

Step-by-Step Working Principle

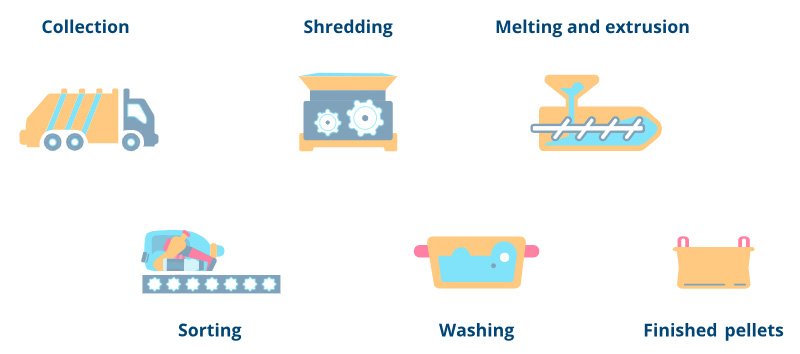

- Sorting & Collection

- Waste plastics are collected and sorted by type (e.g. PET, HDPE, LDPE, PP), color and grade to ensure efficient recycling and high-quality output.

- Shredding & Crushing

- The sorted plastics are fed into a shredder or crusher. Here, larger plastic items are broken down into smaller flakes or fragments, increasing the surface area and making further processing easier.

- Washing

- The shredded plastic fragments are thoroughly cleaned in the washing line. This step removes dirt, labels, adhesives, oils and other contaminants, ensuring the purity of the recycled product.

- Drying

- After washing, the wet plastic chips are dried using a centrifugal dryer or air drying system to remove the moisture, as high-quality recycling requires clean and dry input.

- Melting & Extrusion

- Clean, dry plastic flakes are fed into an extruder where they are heated and melted. The plastic melt is then pushed through a barrel and die to form a continuous plastic strand.

- Pelletizing

- After the extruded plastic strands are cooled, they are cut into uniform pellets or granules by a pelletizer. These pellets are the final recycled raw materials and can be used to make new plastic products.

Summary: The core component of the plastic recycling machine is the screw, which rotates to drive the waste plastic through the mold for high-temperature melting, and finally quickly cools the melted plastic into granules.

How to effectively improve plastic recycling machines?

Next, we will discuss in detail how to effectively improve plastic recycling machines.

1. Integrate Advanced Sorting Technologies

Upgrading machines with automated sorting systems such as near-infrared (NIR) sensors, artificial intelligence (AI) and robotics to effectively separate different types and colors of plastics, thereby increasing purity and improving output quality.

2. Enhance Washing and Drying Efficiency

Implementing multi-stage washing lines, friction washers and high-efficiency dryers. While achieving thorough cleaning, reducing water and energy consumption helps produce higher quality recycled materials and saves operating costs.

3. Optimize Shredding and Crushing Performance

Invest in a wear-resistant, energy-efficient pulverizer/crusher with adjustable settings. Regular maintenance and selection of blades suitable for different plastic types can help increase production and extend the life of the machine.

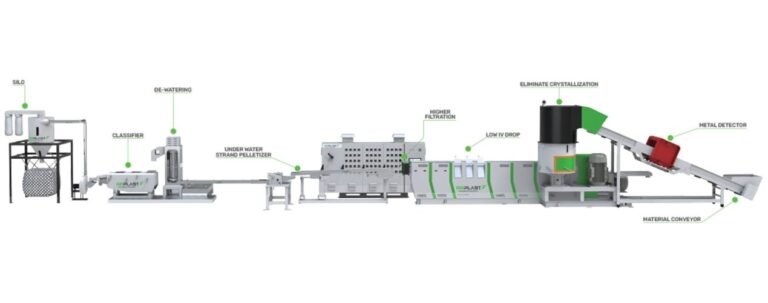

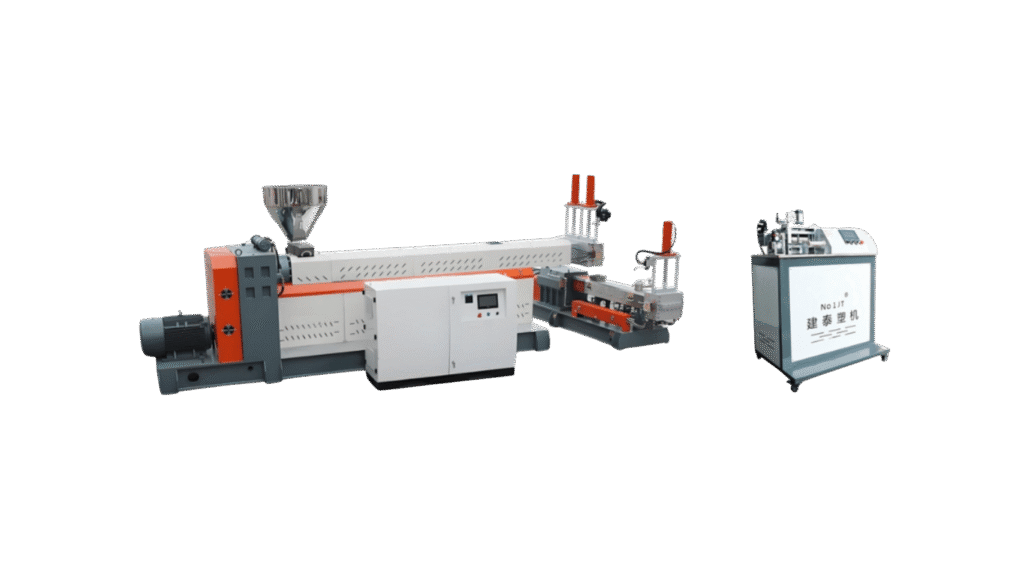

4. Upgrade Extrusion and Pelletizing Systems

Use extruders with better temperature control, degassing systems and filtration to remove contaminants and gases. Improved pelletizing systems ensure uniform pellet size and consistency, increasing the value of recycled pellets.

5. Automate Process Monitoring and Quality Control

Install sensors, PLCs, and IoT connections to monitor temperature, yield, contamination, and other critical parameters in real time. Automated controls help correct problems quickly, reduce downtime, and maintain product consistency.

6. Reduce Energy Consumption

Energy-saving motors, frequency converters and heat recovery systems are used. Heating zones are isolated to minimize heat loss and optimize processing temperature, thus reducing operating costs and carbon footprint.

7. Modular and Flexible Design

Design machines with modular components to facilitate upgrades, maintenance and process customization to handle various types of plastics (film, rigid, foam, etc.).

8. Regular Maintenance and Staff Training

A strict maintenance schedule and ongoing operator training are in place to ensure machines operate efficiently and safely.

Summary Table

| Improvement Area | Action Example | Benefit |

|---|---|---|

| Sorting | NIR sensors, AI vision | Higher purity |

| Washing/Drying | Multi-stage washers, efficient dryers | Cleaner output, cost-saving |

| Shredding/Crushing | Wear-resistant blades, adjustable settings | Higher throughput, reliability |

| Extrusion/Pelletizing | Better controls, filtration, degassing | Consistent pellet quality |

| Automation & QC | Sensors, PLC monitoring | Reduced errors, efficiency |

| Energy Consumption | Efficient motors, heat recovery | Lower operating costs |

| Modular Design | Swappable components, upgrade paths | Adaptability, easier repair |

| Maintenance/Training | Scheduled checks, operator education | Machine longevity, safety |

By incorporating these improvements, plastic recycling machines will run more efficiently, produce higher-quality recycled material, and better serve the growing demand for sustainable plastic solutions.