Plastic Recycling Machines

Leader in plastic recycling machinery, offering complete solutions for PET, PE, PP, and other plastic waste. Over 20 years, JianTai has served 1000+ global customers, helping turn waste into value.

Why JianTai Plastic Recycling Machines?

- 20+ Years of Manufacturing Experience

- ISO & CE Certified

- Customizable Solutions for Various Plastics

- Energy-efficient & Environmentally friendly

- 24/7 After-sales Support

- Exported to 60+ Countries

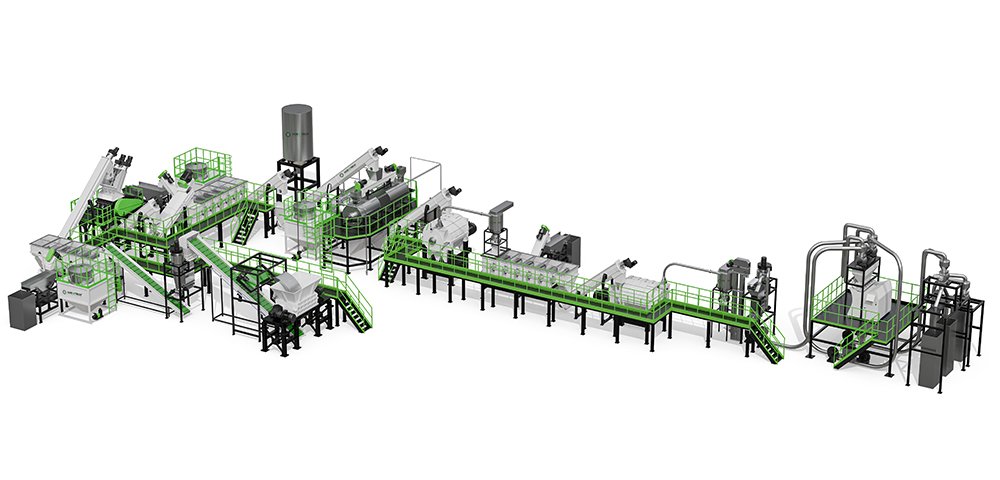

Comprehensive Plastic Recycling Machines For All Needs

Single Screw Plastic Recycling Machine

Our single screw plastic recycling machines are designed for processing a variety of plastic materials such as PE, PP, and PS. Featuring stable extrusion, high output, and easy operation, these machines are ideal for recycling clean and consistent plastic scraps

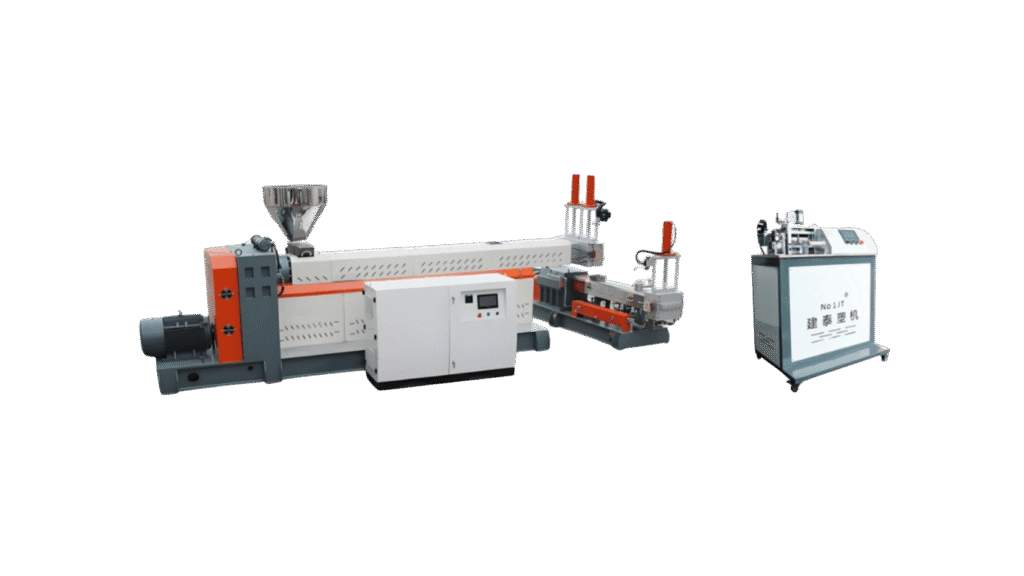

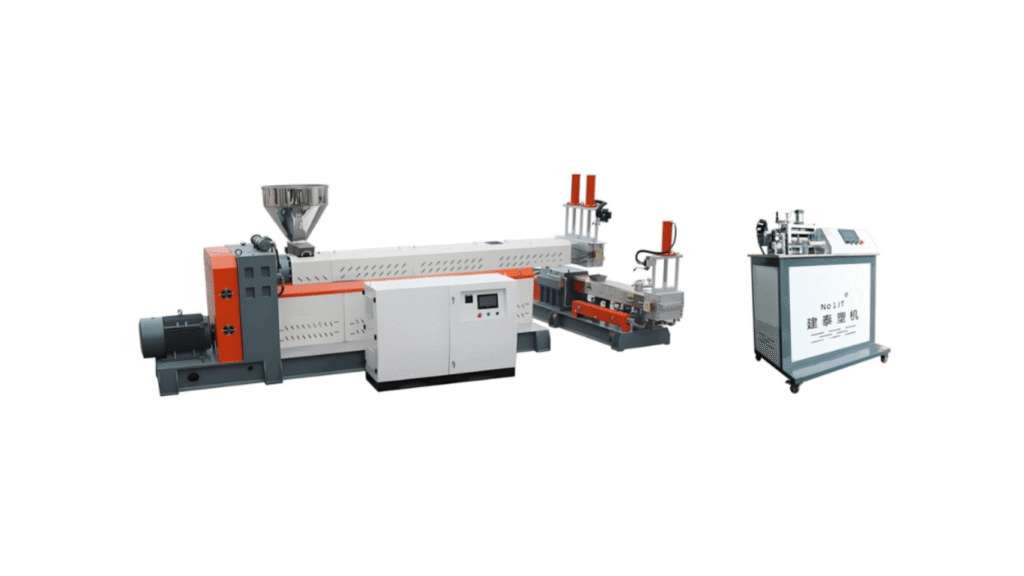

Double Plastic Recycling Machine

JianTai’s double stage plastic recycling machines, also known as “mother and baby” or “tandem” extruders, are especially suitable for processing heavily printed or highly contaminated plastic materials.

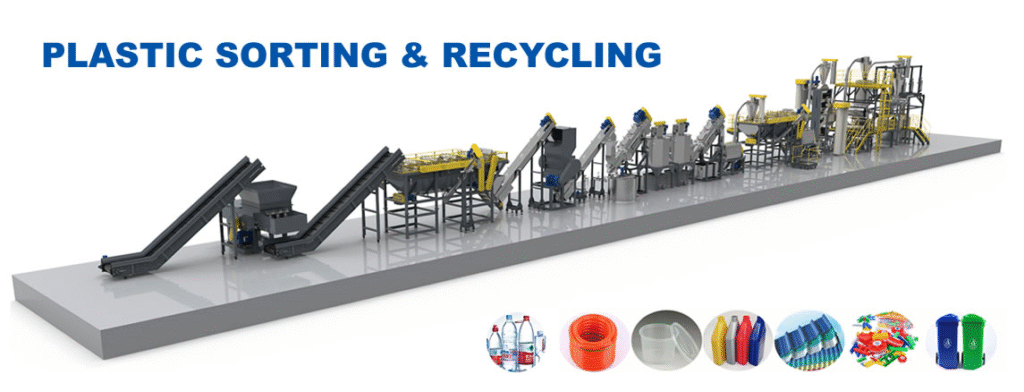

PP/PE Film Washing Line

Designed for recycling all kinds of PP and PE films, this washing line delivers powerful contaminant removal with multiple washing and drying stages. JianTai’s machine guarantees clean, dry film flakes, perfectly suited for further pelletizing or direct reuse.

Plastic Granulator / Pelletizing Machine

Turn plastic scraps into uniform pellets with JianTai’s Plastic Granulator and Pelletizing Machine. Featuring advanced temperature control and automatic feeding, it is suitable for rigid plastics and films, supplying clean raw material for new plastic products.

Let us know what is plastic recycling machine?

Plastic recycling machine is a device or system designed to process waste plastic into reusable raw materials by crushing, melting and remaking it into pellets or new products. It helps reduce plastic pollution and supports the sustainability of resources.

How Plastic Recycling Machines Work

Plastic recycling machines work through several key steps:

- Sorting and Cleaning: Waste plastic is sorted by type and cleaned to remove contaminants.

- Shredding: The plastics are cut into small pieces or flakes.

- Melting: The shredded plastic is heated and melted.

- Extrusion: The molten plastic is forced through a mold to form strands or pellets.

- Cooling and Cutting: The formed plastic is cooled and cut into uniform pellets, ready for reuse in manufacturing new products.

These machines enable the effective transformation of plastic waste into reusable materials.

Advantages of JianTai Plastic Recycling Machine

- Advanced Automation: Incorporates intelligent control systems and real-time monitoring for precise process management and minimal human intervention.

- High Throughput & Efficiency: Engineered for large-scale continuous operation, ensuring maximum material recovery rates and optimized processing speed.

- Energy Efficiency: Utilizes innovative heating and drive technologies to significantly reduce power consumption per output unit.

- Robust Construction: Manufactured with premium-grade, wear-resistant components to ensure prolonged operational lifespan and minimal downtime.

- Versatile Processing Capability: Compatible with a broad spectrum of thermoplastic polymers, including both post-consumer and post-industrial waste streams.

- Consistent Output Quality: Integrated filtration and degassing systems guarantee uniform pellet size, superior purity, and enhanced product value.

- Environmental Compliance: Designed to meet or exceed global environmental and safety standards, minimizing emissions and secondary pollution.

- Modular Design: Allows for flexible configuration and easy system upgrades to accommodate evolving production requirements and technological advancements.

Plastic materials that can be processed by JianTai Plastic Recycling Machine

- Polyethylene Terephthalate (PET)

- High-Density Polyethylene (HDPE)

- Low-Density Polyethylene (LDPE)

- Polypropylene (PP)

- Polystyrene (PS)

- Polyvinyl Chloride (PVC)

- Acrylonitrile Butadiene Styrene (ABS)

- Engineering plastics (such as PA, PC, POM)

- Mixed plastic waste (subject to pre-sorting and compatibility)

Real Case Studies / Customer Testimonials

Rizul Rai

“No one of my known told me you are one of the best in plastic recycling here”

Technical Advantages & Certifications

Core Patented Technologies

JianTai plastic recycling machines incorporate multiple patented designs, ensuring superior performance and high processing accuracy. Our innovative technologies boost productivity and achieve stable operation for any plastic recycling application.

Remarkable Energy Savings

Thanks to advanced engineering, JianTai machines consume up to 30% less energy compared to industry averages. This reduces your operating costs and supports environmental protection efforts.

Durable & Easy Maintenance

Built with high-quality materials and precision manufacturing, our recycling equipment is designed for long-term use. Modular components simplify maintenance and ensure long-lasting reliability, minimizing downtime for your plant.

Fully Certified Quality

All JianTai plastic recycling machines are ISO 9001 and CE certified. We provide complete compliance documentation and display certification logos, giving you peace of mind for safe and legal global operation.

FAQ About Plastic Recycling Machines

What types of plastics can your recycling machines process?

JianTai plastic recycling machines can process a wide range of plastics, including PET, PP, PE, HDPE, LDPE, PVC, and more. We offer customized solutions for both rigid and flexible plastic materials.

How much capacity does your machine support per hour?

Our machines are available in various models, supporting capacities from 200 kg/h up to 3,000 kg/h. We can recommend the best model based on your specific production needs.

What is the delivery time for your plastic recycling machines?

Standard delivery time is 30–60 days after order confirmation, depending on the machine model and your customization requirements.

Do you offer installation and training?

Yes, JianTai provides on-site installation, commissioning, and operator training to ensure smooth machine startup and effective production.

Are your machines energy efficient?

Absolutely. Our recycling equipment is designed for low energy consumption, using up to 20% less power than conventional machines.

What kind of after-sales support do you provide?

We offer lifetime technical support, online guidance, spare parts supply, and 24/7 customer service for all our recycling machines.

Can I customize the recycling line for different plastics or plant layouts?

Yes, we design and build turnkey recycling solutions tailored to your material types and factory space.

Ready to Start Your Plastic Recycling Project?

About JianTai Plastic Machinery Co.

JianTai Plastic Machinery Co., Ltd. (JianTai Machine) was established in 2005 and is located in Yuyao City, Zhejiang Province, China. The company focuses on the research and development and manufacturing of plastic recycling technology and machinery, providing a series of products including plastic extruders, plastic recycling machines, etc. Our products are mainly used in the water-stretching process to convert waste plastics into recycled plastic particles, helping customers effectively solve the problem of plastic waste disposal.